Hydronic Adventures in Rural Ontario

April 26, 2023 | By Paul O'Connor

Contractor shares his experience working with an outdoor woodstove-fired open-loop hydronic system, and how he tied it into a home's closed-loop system.

In mid-November 2022, Paul O’Connor, owner of POC Plumbing and Heating, reached out to share his progress on an interesting project that involved the integration of an outdoor woodstove open-loop hydronic system with an indoor propane-fired boiler closed-loop system in a home in rural Ontario. Following is an edited version of Paul’s correspondence.

This project is in Coldwater, Ont. on a 25-acre bush lot. Initially I was brought in to try and find out why the customer was burning twice as much firewood as everyone was telling him would be necessary. The customer’s outdoor woodstove hydronic system (an open system) was being used to heat the family home and a garage with a workshop.

The hydronic heating in the house uses rads, and the supply and return lines run up into the attic, and the system had no air elimination devices. I don’t know how it even worked without them.

But as I asked questions, I found out they could hear the air and water gurgling around constantly, and therefore they always had to run the outdoor woodstove really hot to heat the rads due to low water flow — the flow sucked.

Ultimately, a heat exchanger was incorporated to separate the open outdoor system from a newer closed-loop indoor system that was run from an oil-burning boiler.

My job was to swap out the oil boiler for a “newer” propane-fired Navien boiler that was reclaimed from a barn, and then also make the entire system work better and more efficiently.

The goal was to use less firewood and use the propane boiler only as a back-up to heat the home.

Wood-burning Central Heating

The system is designed to heat primarily with firewood, which by some is perceived as better than burning carbon from fossil fuels.

If you believe in the philosophy that if a tree blows down and decomposes over 30 years and emits pollution very slowly—but eventually releases 100% of the carbon that tree was holding—then by cutting up and burning that tree in the outdoor woodstove, we’re releasing the same 100% of carbon simply over a much faster period, and you’re also using that same tree to heat your house for a couple of weeks instead of using fossil fuel, so it’s an environmental win.

The outdoor woodstove boiler superheats hot water outside and transports that heat via underground supply and return lines into the buildings.

Figure 1. Woodstove chimney and smaller open pipe (to the right) for the water vessel.

In Figure 1 you can see a big chimney and a smaller pipe coming through the roof. The big chimney is obviously for the firewood exhaust, but the little pipe is for the water vessel. If the water were to get too hot, it can vent out this pipe. The homeowner can also fill the vessel through this pipe, something that gets done every week or so depending on the usage (see Figure 2, below).

Figure 2. Outdoor woodstove panel: you fill the tank until the water in the clear plastic tube in the centre is half way full. The woodstove will blow air on the fire in order to attain the temperature required by the aquastat in the top left corner.

The wood stove boiler is an open system because it is open to the atmosphere, and therefore the system doesn’t require an expansion tank, or 15 psi of water pressure. But it also has to be separated from the closed-loop system in the house and connected via a heat exchanger.

These types of jobs are quite common around farms and rural properties. The advantage is that the woodstove can be a central heating system for two or three buildings on the property at once, and heating is free if you are able to cut your own firewood.

The disadvantage is that you have to be around it to feed the outdoor woodstove all winter. Or the customer must rely on family and friends to keep it burning.

It makes it hard to go on any vacations or hockey tournaments. So, this where I come in.

Open-Closed Integration

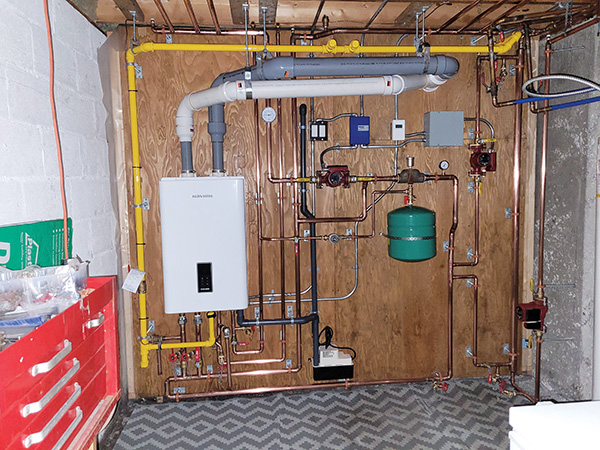

In the house, they have a radiator distribution system with three zones — a system I rebuilt to integrate the propane-fired boiler (Figure 3).

Figure 3. The propane-fired boiler and closed-loop system in the house.

I initially had the boiler turn on with a set point controller set to 140F of the incoming supply water from the outdoor woodstove.

When the woodstove is burning, there was enough heat to satisfy the home to a comfortable 72F. Unfortunately, as it got colder, the outdoor woodstove couldn’t keep up.

I had 180 – 190F water coming through the heat exchanger from the outdoor woodstove, but only 140F coming out of the supply end of the heat exchanger on the closed system.

I had to attain a higher supply temp coming out of the heat exchanger to get the existing rads hotter, so the answer was to add a second heat exchanger.

Custom Heat Exchangers

Plate heat exchangers don’t work well here because the little passages sometimes get plugged up with sediment, especially on the open-loop outdoor woodstove side.

When I started this project I knew very little about the operations of the outdoor woodstove (the open loop side). Fortunately, local outdoor woodstove specialists taught me everything I know about it, and it defied a lot of things I had learned on the closed-loop systems I am more accustomed to.

First is, these specialists tend to make their own copper pipe heat exchangers. I had never seen anything like it.

In Figure 4 (below) you can see how we made the copper heat exchangers. You need a length of 1-½-in. copper pipe, one length ¾-in. copper pipe, and two 1-½ x ¾ x ¾-in. copper tees.

Figure 4. The custom fabricated heat exchangers connecting the open woodstove system and the closed-loop in-house system.

Then somebody hammers the ¾-in. copper pipe right through the tee. Then connect the 1-½-in. copper pipe from the other side and hammer the last tee on from the other side.

The outdoor woodstove loop runs through the ¾-in. copper pipe which is encased by the larger 1-½-in. pipe. It runs constantly all winter. Therefore, a heat exchanger like this won’t clog up or wash out because it is totally laminar flow.

The closed-loop side is tied into the branch sides of the tee and runs intermittently when there is a call for heat. The water runs inside the 1-½-in. copper pipe and contacts the ¾-in. copper pipe and exchanges heat that way.

We initially made a copper tube heat exchanger that’s about six feet long, but it wasn’t able to exchange enough heat for the closed system, so I added a second 10-ft. heat exchanger.

I connected the two heat exchangers in series, so that return water would run through the little heat exchanger first, then come out and enter the second heat exchanger which super heats it. Now I am getting 165F water to send to the rads, and the house is attaining room temperature easily.

Back Up

If the wood fire burns out, the set point controller has a thermal well sensor, and it will command the propane boiler to turn on and heat the rads in the house directly, and this will also provide heat to the outdoor woodstove and the outside building as the heat exchanger basically works in reverse.

If the wood fire burns out, the set point controller has a thermal well sensor, and it will command the propane boiler to turn on and heat the rads in the house directly, and this will also provide heat to the outdoor woodstove and the outside building as the heat exchanger basically works in reverse.

The system has three pumps. The outdoor woodstove pump must run 24/7 during heating season. The pump beside the heat exchanger only runs when either of the zone valves are calling for heat or if the boiler is running.

One of the home’s three zones is protected by a WiFi thermostat in case a pump or zone valve breaks, or if the customer runs out of propane while he is on vacation. If that happens, the thermostat will send a notification so the customer can address the issue and prevent a potential freeze.

This past fall the system started up on just propane for the first month until the wood was delivered. It took about a day to iron out the bugs, but the system is working flawlessly now.

The customers are very happy, and the only thing left to do next year is tie the electric hot water tank into this system so the wood stove can heat that as well. <>